Inventory Of The Most Commonly Used Liquid-liquid Separation Equipment In Laboratories

Rotary evaporator

Rotary evaporator, referred to as Rotavapor (rotovap), is mainly used for the separation or purification of substances with different boiling points. The rotary evaporator is generally composed of 1. rotary motor 2. evaporating flask 3. vacuum system 4. fluid heating pot 5. condenser 6. condensing sample collection bottle and so on. When working, the rotary evaporator continuously heats and distills the mixture, and then cools and collects different fractions, so as to achieve the purpose of separating different substances.

Thin film evaporator

The thin film evaporator has the same principle as the rotary evaporator and is also used for the separation of substances with different boiling points. After the material enters the evaporator, it is rapidly formed into a film by agitating the scraper; the heat source is heated and exchanged with the material liquid through the cylinder wall; the liquid film boils and vaporizes, enters the condenser, condenses into a liquid and discharges, and the concentrated liquid is released from the bottom outlet . At present, foreign thin film evaporators have been developed in the direction of large-scale, serialization and generalization, and have been widely used in distillation, separation, concentration, extraction, deodorization, degassing, reaction and other processes.

Molecular distillation

Molecular distillation is a special liquid-liquid separation equipment. It is different from the traditional distillation which relies on the separation principle of boiling point difference, but realizes the separation by the difference in the mean free path of molecular motion of different substances. When the liquid mixture flows along the inner wall of the main evaporator and is heated, light and heavy molecules escape from the liquid surface and enter the gas phase. Because the free paths of light and heavy molecules are different, molecules of different substances move at different distances after escaping from the liquid surface. Through the built-in condenser tube of the main evaporator, the light molecules reach the condenser tube and are discharged, while the heavy molecules cannot reach the condenser tube and are discharged along the mixed liquid, so as to achieve the purpose of material separation.

Short path distillation

Short path distillation is designed according to the principle of molecular distillation. It is a model for simulating molecular distillation. Because the distance between the heating surface and the condensation surface is very close and the resistance is small, it is called short-path distillation. The short-path distillation condenser can instantly liquefy the gas phase material, so it can maintain a high vacuum inside the equipment, especially suitable for materials with high boiling point under normal pressure and difficult to separate by ordinary separation methods.

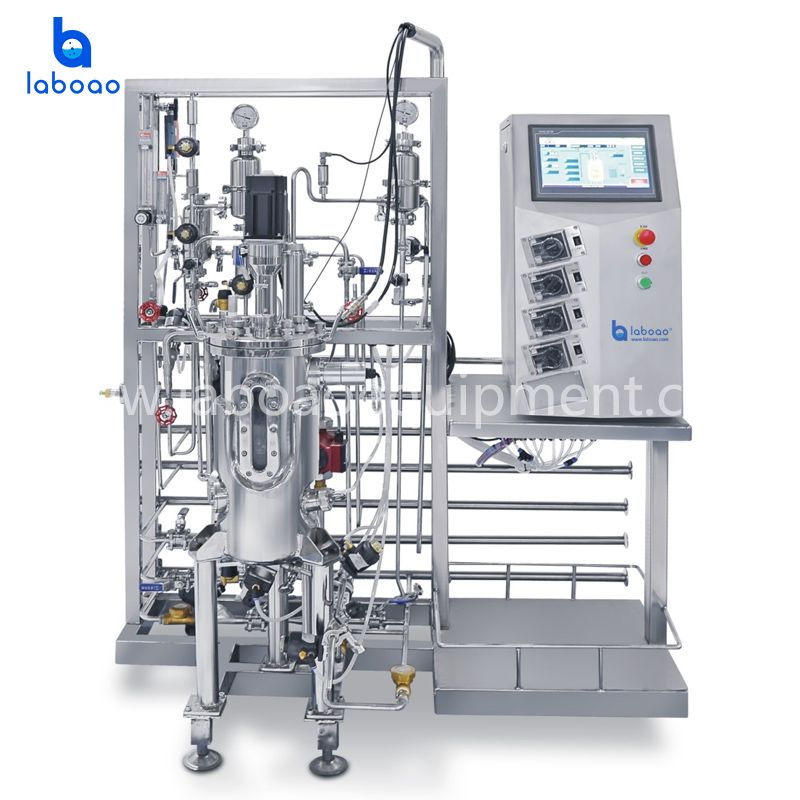

Liquid dispenser

Different from other equipment, the liquid separator mainly uses the characteristics of two liquids that are incompatible with each other. The liquid with higher density will sink to the bottom of the container and can be separated under the action of gravity. Generally, the separator can also be used for liquid-liquid extraction and stirring reaction at room temperature when it is equipped with a stirring paddle. The reaction material can be discharged from the discharge port at the bottom of the kettle, and the operation is convenient.

In addition, centrifuges, liquid chromatographs, etc. are also commonly used equipment for liquid-liquid separation experiments. During the experiment, we should make the best choice according to the material characteristics, separation purpose and experimental cost.

-analyzer-1695623743955.jpg)