What Types Of Bioreactors Are Commonly Used In Laboratory?

Whether animal cell culture technology can be industrialized and commercialized on a large scale depends on whether a suitable bioreactor can be designed. Due to the great difference between animal cells and microbial cells, traditional microbial reactors are obviously not suitable for large-scale culture of animal cells. First of all, it must be satisfied that under the condition of low shear force and good mixing, sufficient oxygen can be provided for cell growth and cell synthesis of products.

So what are the types of bioreactors commonly used in the laboratory? According to the material of the reactor, they can be divided into glass tank reactors, stainless steel reactors and disposable reactors.

(1) Glass bioreactor

At present, most of the reactors used for process development and research at home and abroad are mainly glass tanks. The glass tank bioreactor has the characteristics of flexible configuration, powerful functions, simple operation, and easy upgrade and expansion. It is a research and development project for animal cell culture and microbial fermentation. The best choice for animal cells, Escherichia coli, yeast, fungi, insect cells and plant cell culture.

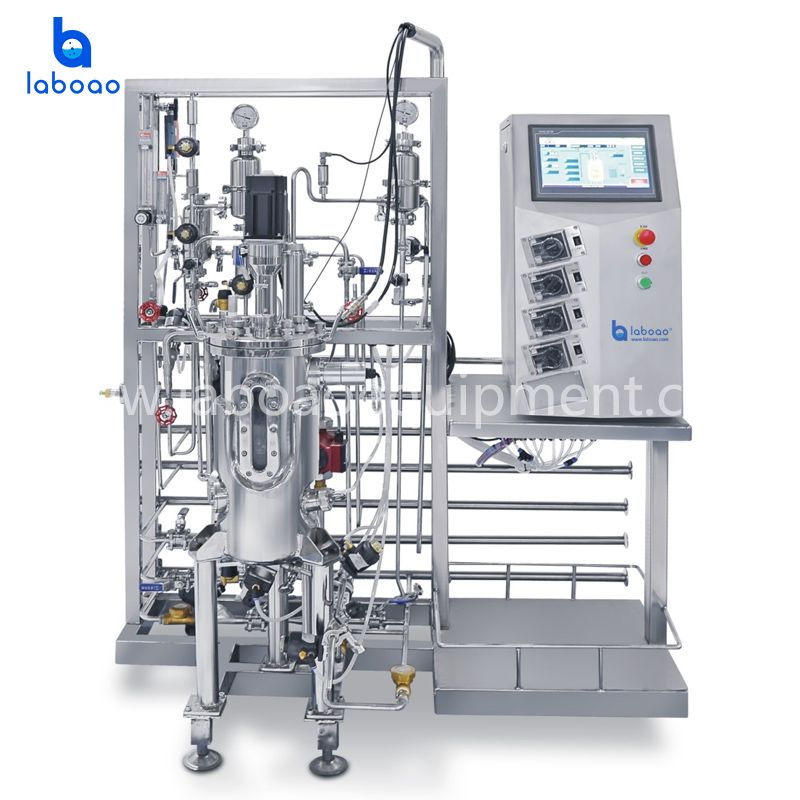

(2) Stainless steel bioreactor

To date, almost all FDA-approved antibody drugs are produced in stainless steel reactors. Due to the low yield of early antibodies, the production scale is mostly around 10 000 L. Stainless steel reactors usually involve CIP modules, SIP modules, storage modules, etc., so the pipeline connection is very complicated and requires high operators. In the event of contamination, the entire system needs to be checked and sterilized. At the same time, stainless steel reactors also face high up-front equipment investment and operating costs.

(3) Disposable bioreactor

In recent years, single-use reactors have rapidly occupied domestic and foreign markets with their advantages of no cleaning, no sterilization, and flexible operation. Enzyme preparations from Shire under the trade name VPRIV® are produced in single-use reactors and have been approved by the EMA for marketing. Compared with the traditional stainless steel reactor, whether it is cell growth, antibody yield, or antibody quality, the single-use reactor can achieve a high degree of similarity, and at the same time, it can significantly reduce the production cost and shorten the production cycle.

With the rapid development of cell line construction technology and medium development technology, the cell density and antibody yield have been greatly improved, posing severe challenges to large-scale cell culture.

The rapid rise of single-use reactors has brought a huge impact on traditional stainless steel reactors. Because single-use reactors significantly increase operational flexibility and reduce contamination risks while reducing the bulk of CIP, SIP, and related validation work. If the leachables/precipitates and production scale problems can be solved well, it will be possible to replace stainless steel reactors and become the mainstream reactors for antibody production in the future. In addition, because the main basis of the reactor scale-up is still based on the empirical scale-up principle, and there are still some controversies, such as the suitability of the tip velocity as the scale-up principle. These factors undoubtedly increase the difficulty and risk of the future industrialization of antibody drugs.

-analyzer-1695623743955.jpg)