DESCRIPTION

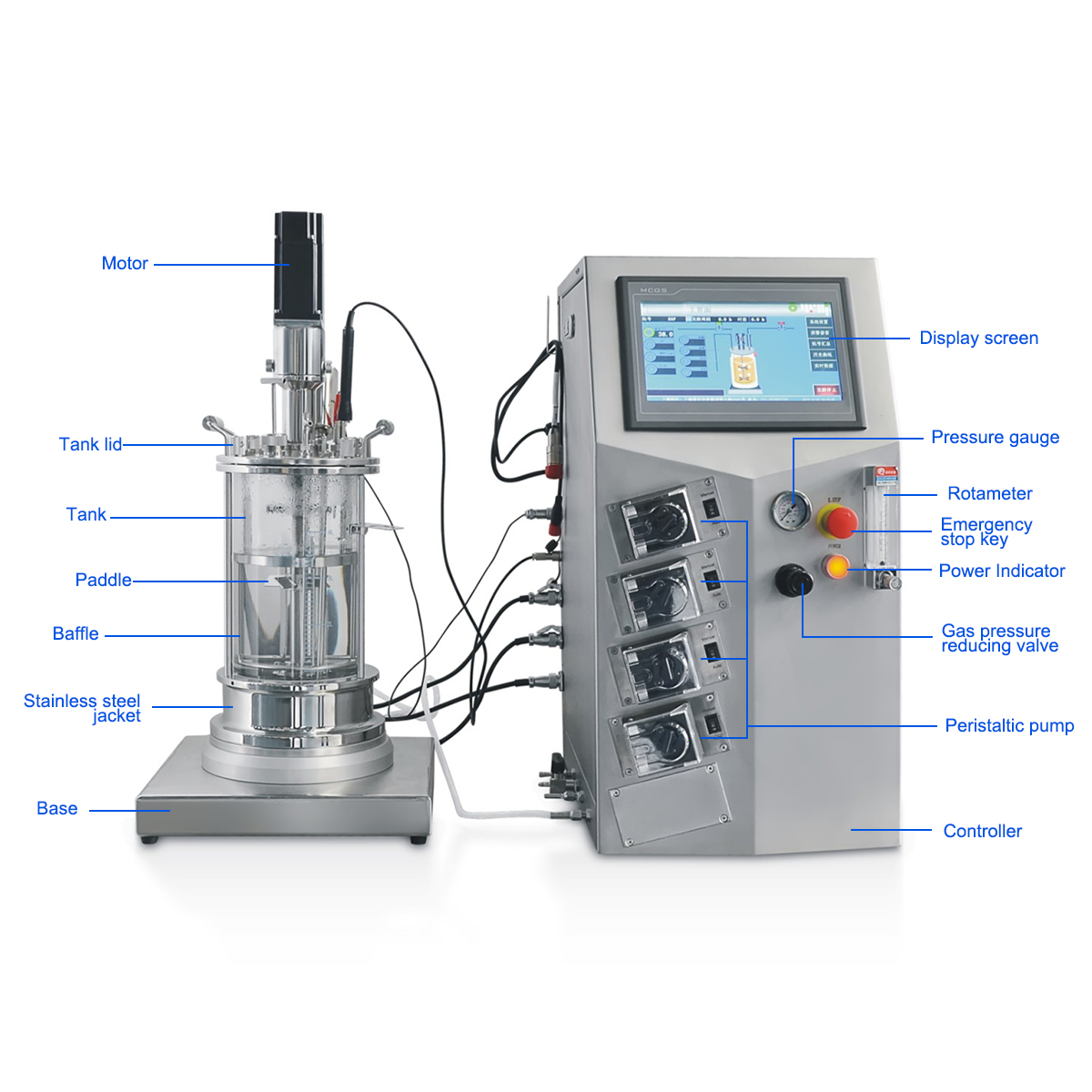

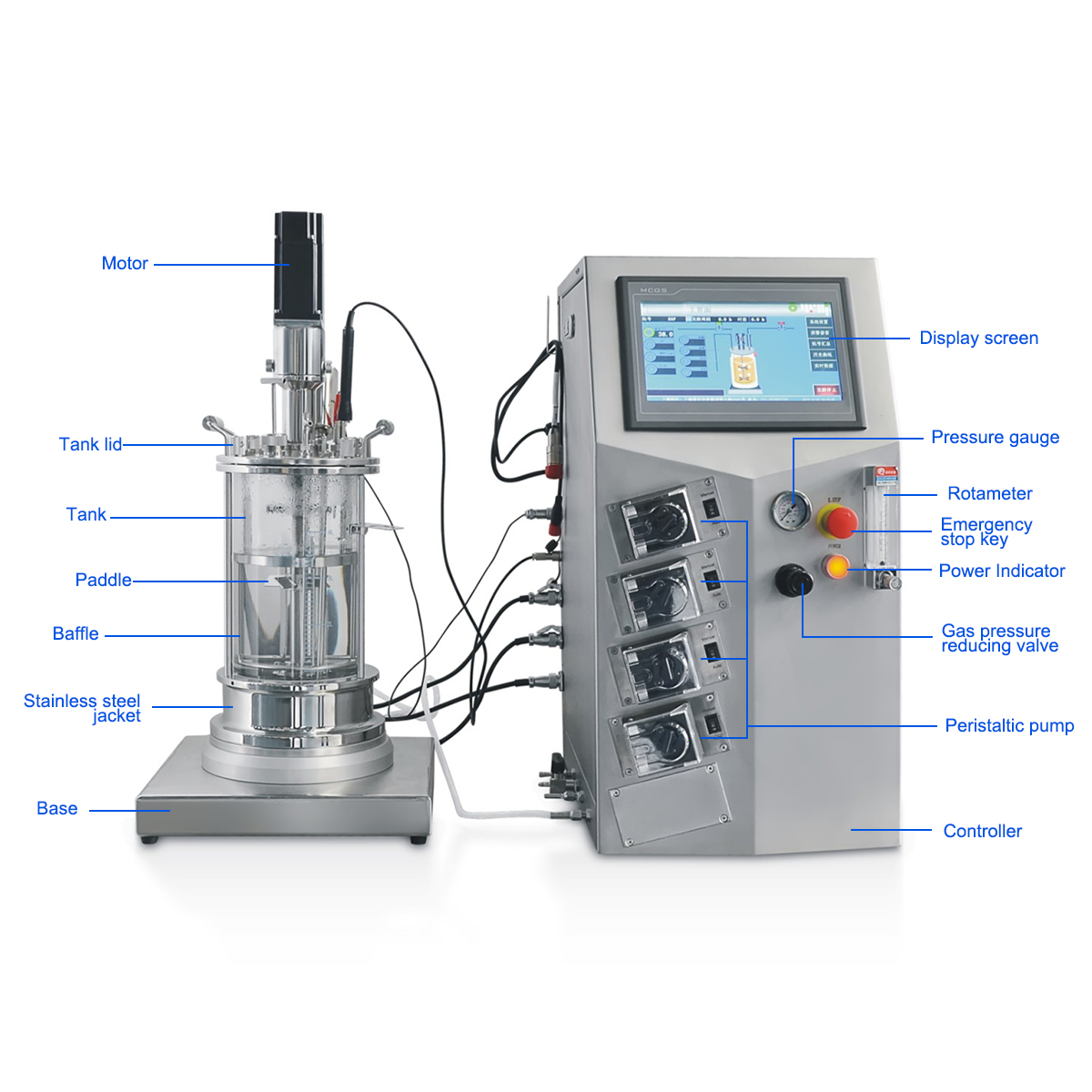

Multiple glass bioreactor is four peristaltic pumps are installed on the front of each tank, which can supply acid, alkali, defoamer and culture medium to the fermentation tank. Various parameters in fermentation such as pH, DO, temperature and speed can be monitored by the controller, and all data and control parameters can be transmitted to the controller or computer.

The structure is compact, and various components can be integrated into the fermentation system. It adopts the direct coupling mechanical stirring method driven by the upper part, which has a simple structure and stable operation. It is suitable for parallel orthogonal experiment, provides the most optimized way for process research, and shortens the precious time of research.

FEATURES

1. Siemens PLC control system + vinylon LCD touch screen, is used to display all measured values and control parameters, which greatly facilitates the user's operation. you can use USB for data transmission, sampling and displaying tank data, browsing and analyzing system data, reading settings.

2. Each tank is equipped with 4 peristaltic pumps beside the front tank, which can supply acid, alkali, defoamer and culture medium to the fermentation tank.

3. Various parameters in fermentation such as pH, DO, temperature and speed can be monitored by the controller, and all data and control parameters can be transmitted to the controller or computer.

4. The structure is compact, and various components can be integrated into the fermentation system.

5. It adopts the direct coupling mechanical stirring method driven by the upper part or the magnetic indirect coupling mechanical stirring method driven by the lower part, which has a simple structure and stable operation.

SPECIFICATIONS

Model | LBR-XGJGG-6 | LBR-XGJ-(8-12)H |

All Capacity | 0.6L/1L/2L/3L/5L/7L/10L |

Material | 316L stainless steel+borosilicate glass |

Mixing method | Magnetic/Mechanical stirring | Mechanical stirring |

Sterilization method | off-site sterilization |

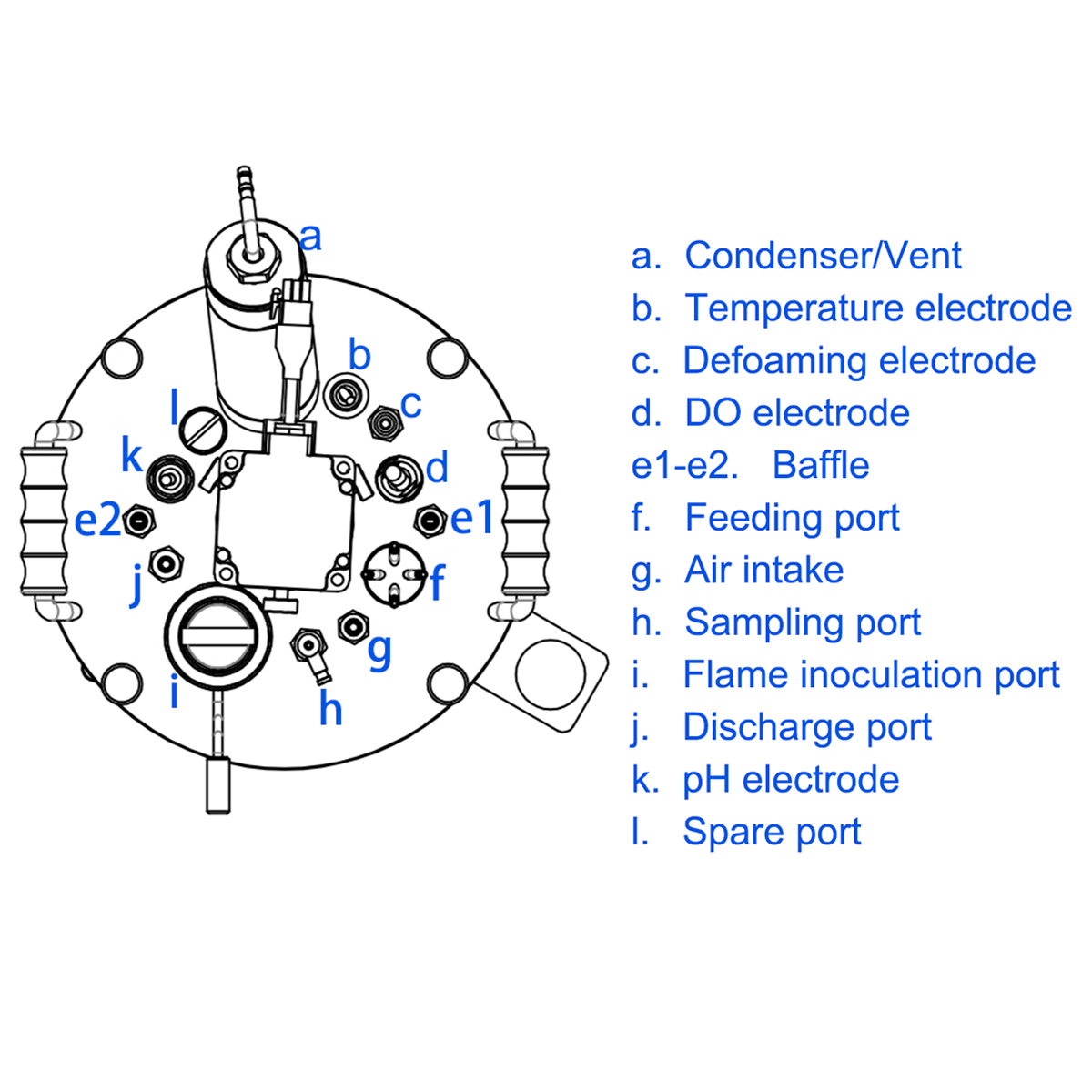

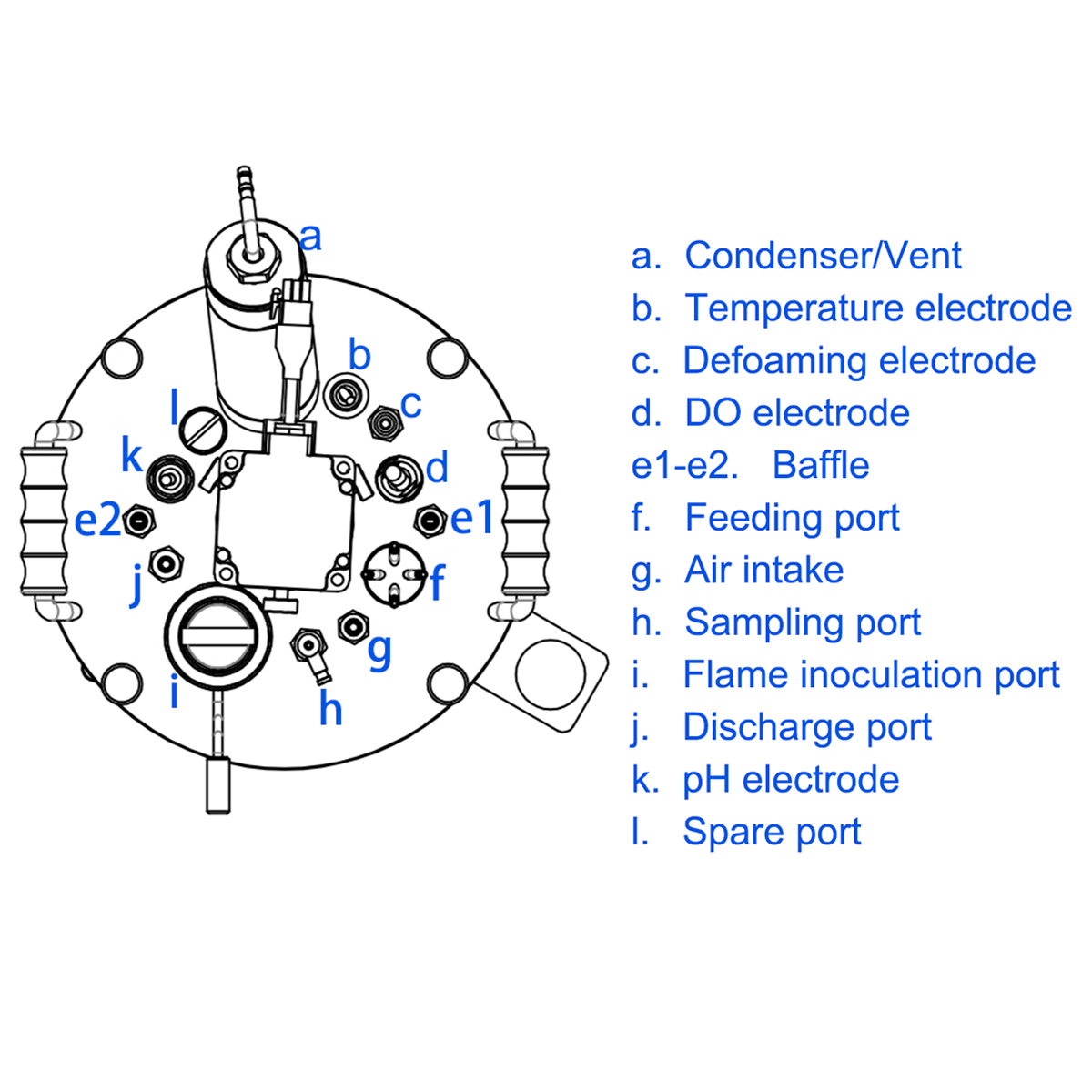

Basic Configuration | Temperature, Speed, PH, DO, Defoaming, Ventilation, Pressure |

Extensible configuration (optional) | Exhaust O2, CO2 detection, Online detection of methanol and ethanol content, Refill weighing system etc. |

WHY CHOOSE US

- Factory direct sales with competitive price.

- Premium quality with CE & ISO certification.

- Strong product OEM & ODM customization capability.

- Promise production & on-time delivery.

- Perfect after-sales service, free product accessories.

- 15 years of experience in R&D and production of glass bioreactor fermenter machine.

OUR FACTORY

We have a standard production workshop and a complete production team. They always produce a serious and responsible attitude to produce each product. Our R&D team is made up of multi-aspects professional engineers such as design engineer,technology specialist ,qualified specialist and process control manager, etc. Our qualified specialists strictly realize the process comprehensive supervision based on our quality process control system, which contains products design, research and development, test, production, quality inspection and packaging.

PACKAGING & SHIPPING

Our product packaging has been proven over the long term and we usually have plywood boxes or cartons with trays. We will arrange the appropriate packaging according to the weight and size of the goods. Of course, you can also choose the packaging form.

CUSTOMER CASES

Our laboratory instruments and equipment are used in many scientific laboratories, scientific research institutions, universities, hospitals, centers for disease control and other institutions, and are combined with many well-known biopharmaceuticals, new energy, electronics companies, food processing, environmental protection, etc. Enterprise cooperation, our stable and reliable products are exported to more than 120 countries around the world, and have been highly recognized by them, believe LABOAO, we grow together!

AFTER-SALE WARRANTY

Authenticity GuaranteedWe assure you purchase our products are 100% certified products.

24*7Hours ServiceProvide 7*24 hours service telephone & support email to help you solve problems quickly.

Technical SupportProvide equipment installation, adjustment, operation training, etc.

1 Year WarrantyFree maintenance and accessories within warranty period(not caused by human factors).