Practical Functions Of Solid State Fermentation Tank

The solid-state fermentation tank has six functions of material dry mixing, wet mixing, sterilization, inoculation, fermentation, and mechanical discharge. The in-situ continuous operation in the tank, especially after the material is sterilized, the inoculation and fermentation processes can It is an ideal multi-functional solid fermentation equipment, which is carried out in a sterile state. It is suitable for biological preparation products with good bacterial strain resistance and loose solid medium material, which is not easy to gelatinize.

This equipment adopts media such as steam or ozone to sterilize materials in situ. When using steam sterilization, if the medium material has high starch content and is easy to gelatinize, its moisture content should be strictly controlled below 20% before sterilization. When using ozone to sterilize, it is not necessary to humidify the solid medium material, and it is sufficient to maintain the original natural moisture content, which is generally about 8%-15%.

Equipment composition:

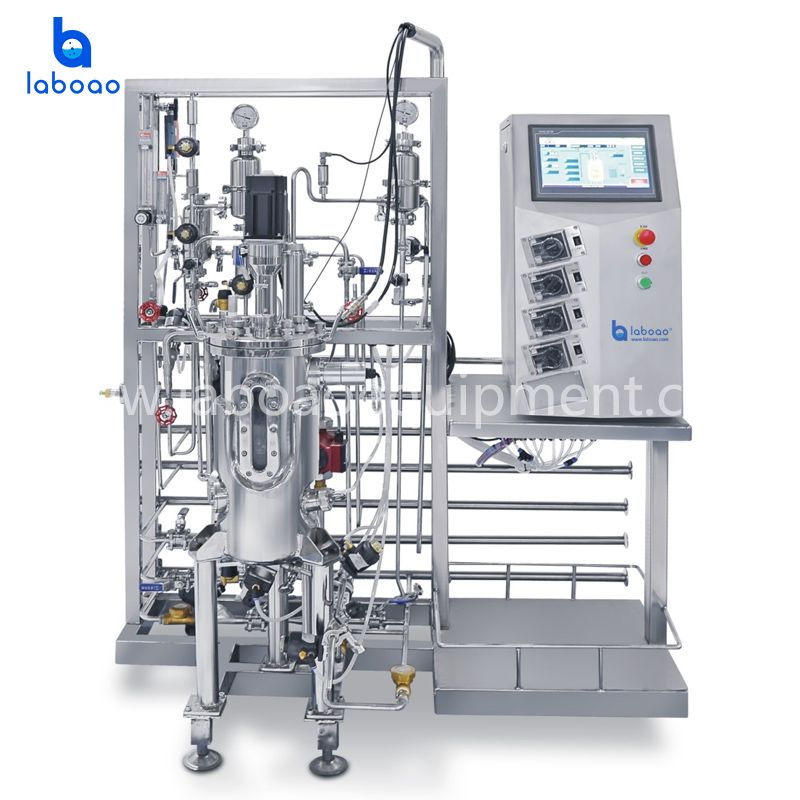

The solid-state fermentation tank is mainly composed of a fermentation tank, an air treatment system, a steam purification system, an electrical control system, a constant temperature system and pipelines, valves, auxiliary systems, sensors and primary instrumentation systems, and a lower computer control system (on-site PLC control system, secondary instrument), upper computer system and bench etc.

Features of solid-state fermenter:

1. In-situ sterilization and cooling: Steam is directly introduced into the solid-state fermentation tank, supplemented by a special stirring system, to sterilize the medium material in-situ. Compared with the traditional turntable type and tillage type solid fermentation equipment, it saves a lot of auxiliary equipment such as solid material steamer and aseptic material conveying system. The cooling adopts the combination of jacket circulating water and ventilation, and at the same time adjusts the moisture content of the sterilized material.

2. Temperature and humidity control: digital display of temperature, automatic control by external circulating water; material humidity is adjusted by full atomization water replenishment system.

3. In-situ inoculation: In-situ differential pressure inoculation. Supplemented by stirring, the inoculation is uniform.

4. Power drive: The AC motor is used to stir the materials at a fixed or adjustable speed, so that materials with different physical properties and bacteria with different characteristics can be well fermented.

5. Air aseptic conditioning system: It can be connected with low-energy medium-low pressure fans for ventilation. The air is processed by the high-efficiency sterilization system and then enters the fermenter to ensure a sterile environment.

6. Special specifications can be customized.

-analyzer-1695623743955.jpg)