DESCRIPTION

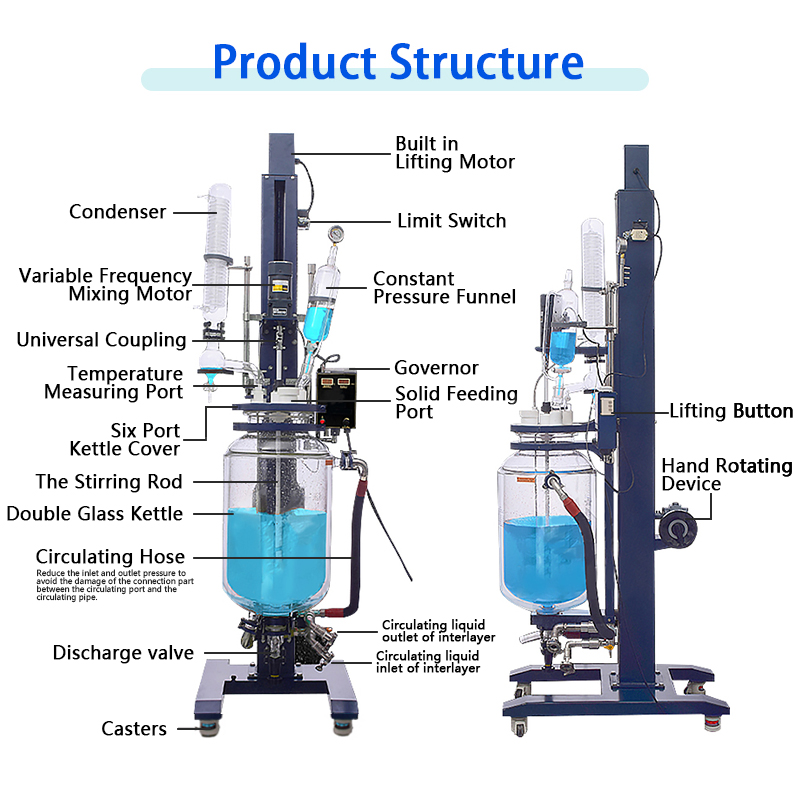

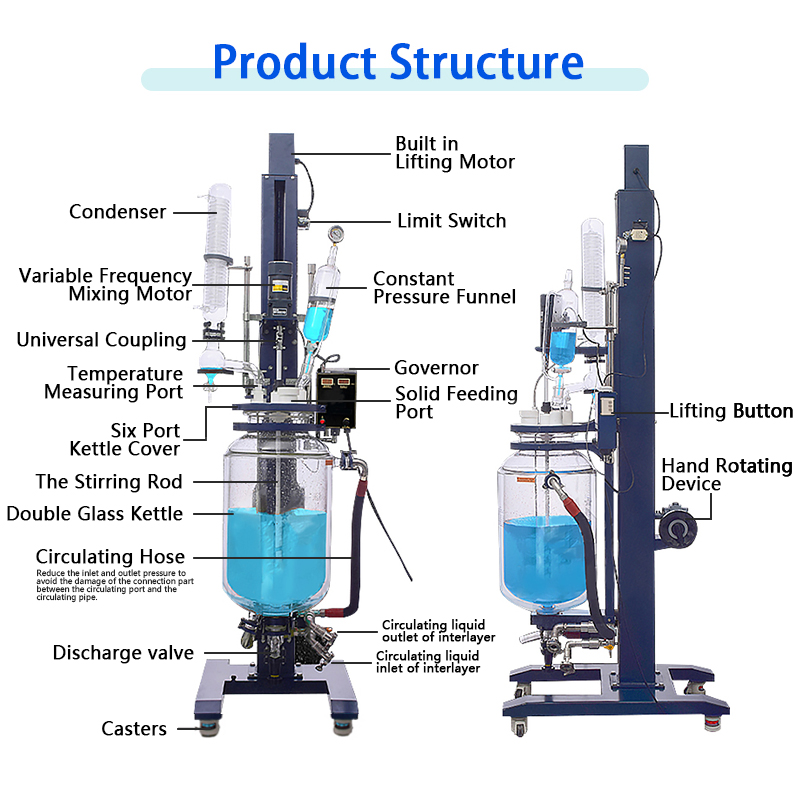

1. This machine has an electric constant speed stirring system, a condensation dripping system, and the interlayer of the kettle body needs to be connected with external heating or cooling circulation equipment.

2. While stirring the materials, the heating bath heats the contents of the kettle, which can improve the evaporation efficiency under vacuum conditions.

3. When the solvent vapor passes through the glass condensing coil, it is cooled to liquid, which can be returned to the kettle or recovered through the recovery bottle.

4. The lifting and rotating reaction kettle is based on the ordinary reaction kettle, which can make the kettle cover and the part above the kettle cover rise as a whole. After the stirring rod leaves the kettle body, the kettle body can be rotated 150 degrees to the left by the handwheel, and poured out directly. Materials, easy to clean the kettle body.

FEATURES

1. The glass is made of high borosilicate glass (expansion coefficient 3.3), which can be used in the range of high temperature (250°C) to low temperature (-80°C), and has good high temperature resistance, acid and alkali resistance, and corrosion resistance.

2. The kettle body is made of three layers of glass, forming an inner interlayer and an outer interlayer. The inner interlayer is connected with cold and hot circulating liquid, and the outer interlayer is vacuumed to maintain the temperature of the materials in the kettle.

3. The main bracket is made of square steel anti-corrosion spray + aluminum alloy + stainless steel material, which is anti-corrosion, anti-oxidation, stable, beautiful and durable.

4. The kettle cover is made of polytetrafluoroethylene, which has good sealing performance, corrosion resistance, acid and alkali resistance.

5. The kettle lid and the part above the kettle lid can be lifted and lowered electrically, and the kettle body can be rotated 150° to the left by the hand wheel, which is convenient for cleaning and manual rotation.

6. Glass + PTFE discharge valve, discharge on the side without liquid accumulation, and recover the solution very quickly.

7. After the inlet and outlet of the jacket are connected to stainless steel hoses, they are fixed to the bracket and then connected to the external circulation pipe to reduce the pressure of the inlet and outlet liquid, and also to avoid damage to the connection between the glass interlayer circulation port and the circulation pipe.

8. Low-speed booster motor, frequency conversion speed regulation, fine-tuning through the knob, double-display speed control box can digitally display the speed and the temperature of the material in the kettle, stable performance, clear display control and data plane, easy to operate.

9. The stirring system adopts ceramic bearings and mechanical seals to prevent the stirring rod from being worn and chipped. It is resistant to high temperature, wear and tear, and has good sealing effect.

10. Adopt PT100 temperature sensor, 304 stainless steel material, transparent PTFE tube, double anti-corrosion.

11. The vacuum pressure gauge shows the real-time vacuum, and the pointer shows it.

12. Crescent-shaped stirring paddle, 304 stainless steel + PTFE stirring blade; the stirring rod is made of 304 stainless steel, covered with PTFE tube, with high strength and strong corrosion resistance.

13. There is a Foma universal wheel with brakes at the bottom of the machine, which can be moved as a whole and is easy to operate.

14. The stirring and lifting fuses have high protection performance.

CUSTOMER CASES

Our laboratory instruments and equipment are used in many scientific laboratories, scientific research institutions, universities, hospitals, centers for disease control and other institutions, and are combined with many well-known biopharmaceuticals, new energy, electronics companies, food processing, environmental protection, etc. Enterprise cooperation, our stable and reliable products are exported to more than 120 countries around the world, and have been highly recognized by them, believe LABOAO, we grow together!